HALF-CUT CELL SOLAR PANELS

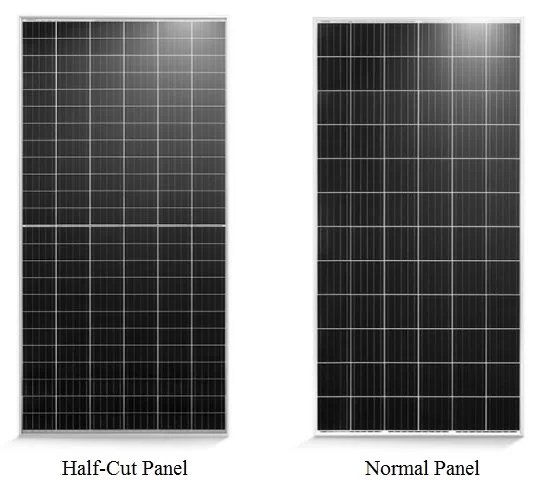

Half-split solar panels are panels that are formed by splitting the cells used in conventional panels in half and have some advantages as a result of this process. Instead of being made up of 60 or 72 cells like conventional panels, half-split solar panels are made up of 120 or 144 half-sized cells with the same structural dimensions as shown in Figure 1. Thus, a lower electrical resistance of the internal structure of the panel is achieved and the efficiency of the panel is improved. In addition, half-split panels perform much more efficiently than conventional panels in shading due to the customisation of not only the division of the cells in half, but also the shape of the connection in the panel’s internal structure. Many major panel manufacturers predict that the market share of half-cut panels will increase to 40% by 2028, given the current state of technology.

Current Value and Resistance

When a solar cell is cut in half, it has a resistance of a quarter of a normal cell and produces half the current. In this context, although the halved cells produce half the current of normal cells, since their number is twice as much as normal cells, when we connect these cells together and form a half-cut panel, the current produced by the resulting panel is equalised with the current value produced by a normal panel, while its resistance is halved. As a result of all these, the life of the panels is extended, power losses are reduced by 4 times and efficiency is increased.

Turnaround Time

In addition to having technical advantages, half-cut panels also reduce the payback period of solar energy investment. They provide much shorter payback periods than normal panels, especially in places where shadowing is predicted to occur and where there are space restrictions. In this context, with the help of the relevant panels, cost-effective investments can be made without sacrificing quality and output power.

Connection Type

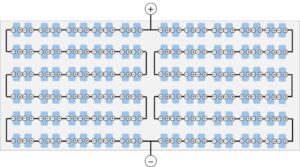

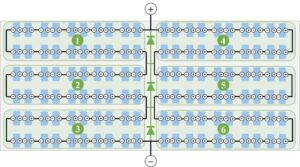

A typical normal solar panel consists of 60 cells connected in series, each with a voltage of 0.5V. Since the voltages are summed in series connections, the total voltage of the panel is 30V. If the internal connections of half-cut panels are made like normal panels (Figure 2), they produce half the current and twice the voltage of normal panels. This is not a desirable situation as it will complicate the operating conditions of the inverters used in the sector. Therefore, in order for half-cut panels to operate at the voltages at which normal panels operate, their internal connections are made in a different way as shown in Figure 3. Instead of connecting all the cells in series, two groups of 60 half-cut cells are connected in series, each with an output voltage of 30V. These groups are then connected in parallel to each other and the 30V voltage is not exceeded.

2.Panel where Half-Cut cells are connected like normal cells

Figure 3. Correct connection form of Half-Cut cells.

Figure 4. Cell arrays in half-cut panels.